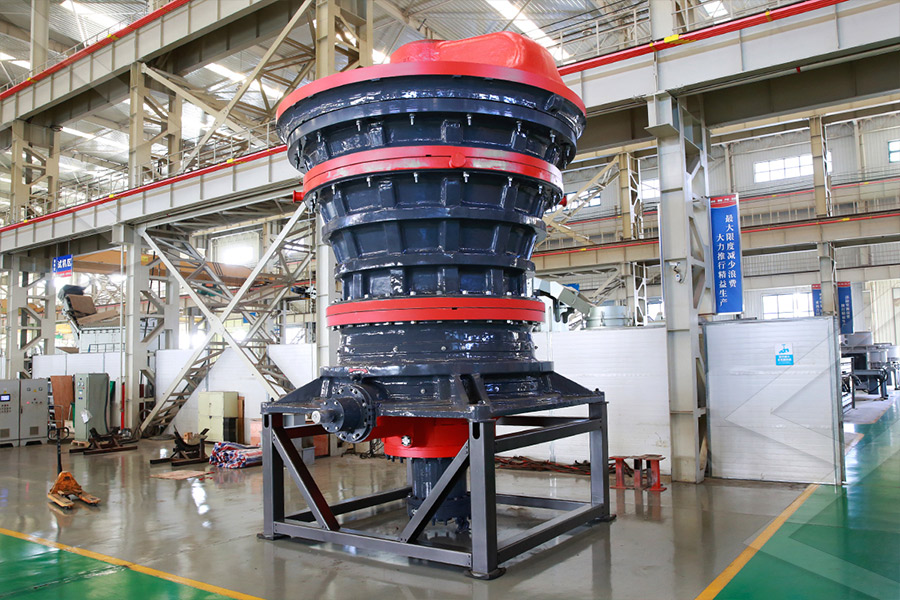

Cone Crusher Plant India Aggregate And Slag Crushers

.jpg)

Cone Crusher thyssenkrupp Industries India

Proven quality – great flexibility – easy operation In the Cone Crusher the material is crushed by compressive forces between the Crusher shell mantle The Crushing Chamber is designed to customer specifications 2020年2月8日 — Cone crushers are like gyratory crushers, except that the outer crushing surface takes the form of an upwardpointing apex, which results in the two crushing Aggregate Production Optimization in a StoneCrushing Plant Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw The higher cavity density improves the interparticleCone Crusher Manufacturer Propel IndustriesThe main components of a cone crusher include the main shaft, mantle, concaves, cone, eccentric bushing, drive, crown gear, frame, and tramp release mechanism (mechanically or hydraulically actuated)Cone Crushers (Parts of a Cone Crusher)

.jpg)

CRUSHING SCREENING SOLUTIONS

2024年4月14日 — cone crushers from Astec Aggregate Mining Group (AAMG) for consistent performance The experience shows in today’s comprehensive line of AAMG 2024年9月7日 — Currently, we deliver endtoend crushing plants and MANUFACTURE all the equipment: Jaw crushers, Cone crushers, Sand making cones, VSIs, vibrating screens, grizzly feeders and balance of COREThe Trio® TC Series liveshaft cone crusher is designed for secondary and tertiary crushing within mining, aggregate or industrial applicationsTrio® TC Series Cone Crusher Weir Weir Groupstone vsi crusher manufacturer in india Crushers,Crusher Machines,Jaw Crusher manufacturer,Tyre supplies crushers and spare wear parts for stone quarry, mine mining in USA, UAE, Japan, South Africa stone crusher aggregate, cone crusher crushing capacity Home >> Rock Crushing Plant stone crusher aggregate, cone crusher VSI Crushe Stone Crusher Japan Technology Crusher Mills, Cone Crusher

.jpg)

Understanding the Cone Crusher Working

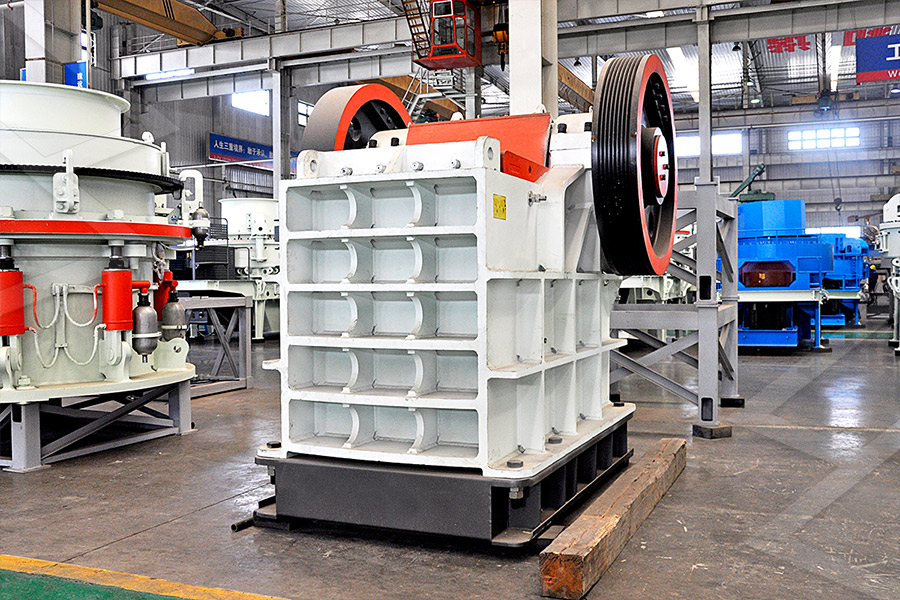

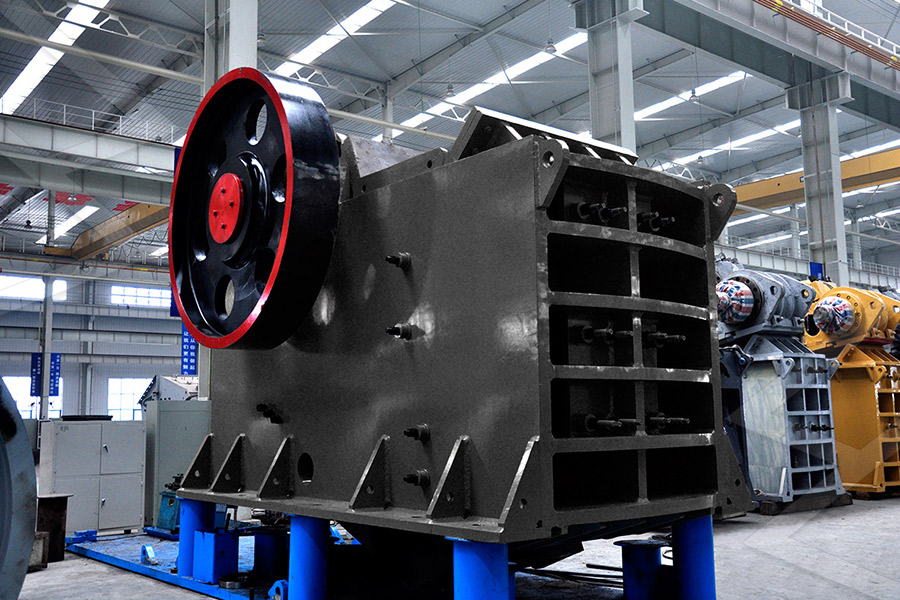

2023年2月23日 — A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone Engineered for all rock types, Nordberg® GP Series™ cone crushers can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations Nordberg® GP Series™ Cone crushers for demanding crushing needsThis is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Sandvik CH cone crusher The open side and closed As the feed is crushed, it falls and exits the crusher through the space at the bottom The eccentric gyration of the mantle means that at any moment this space Cone crusher basics in 4 minutes SRPMechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy Jaw Crushers AGGRETEK Jaw Crushers for aggregate

.jpg)

Crushing and Screening Handbook AusIMM

2021年6月24日 — the crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit all2024年9月24日 — The Powerscreen 1000 Maxtrak portable cone crusher has been designed for direct feed applications without prescreening on clean rock Cone Crushers; Impact Crushers; Screening Inclined Screens; Scalping Screens; The Powerscreen® 1300 Maxtrak is a portable cone crushing plant which is ideally suited to secondary Cone Crusher 1000 Maxtrak Powerscreen2024年3月25日 — Mellott is the East Coast Aggregate Powerhouse, providing rock crushers for sale and rent in Florida, Georgia, Alabama, Tennessee, Virginia, West Virginia, Maryland, Pennsylvania, South Carolina, North Carolina, New York, Ohio, New Jersey, Delaware, Connecticut, Massachusetts, Vermont! When selecting a cone crusher for your Comparing the Metso HP200 and HP300 Cone Rock Crushersrolling mill slag crusher cost – Crusher Manufacturer Copper / Ore / Steel Slag Crusher plant and Grinding Mill Slag Crushing Plant For steel productionPortable Copper Ore Crusher Vertical Roller Mill Roller Mill Crushing Slag Crusher Crusher Mills, Cone Crusher

.jpg)

Cost Sheet of Stone Crusher Plant in India CM Mining

2023年12月8日 — drivespreadsheet Total cost The total cost of setting up a stone crusher plant in India can range from ₹5 million to ₹20 million The specific cost will depend on a number of factors, including the size and capacity of the plant, the type of equipment used, the location of the plant, and the government regulations and environmental impact Cone Crusher Plant India Aggregate And Slag Crushers Crushing MachinesPlants at Best Price in Aesha Conveyors And Crushing Equipment Contact Supplier Amey Engineers Paper Fine Crusher, Shredding Capacity: 1500 kg/hr, Model Name/Number: Ns 300 ₹ 165 Lakh Amey EngineersCone Crusher Plant India Aggregate And Slag Crushers1 天前 — Superior’s Patriot Cone Crusher is an Americanmade, bushingstyle rock crusher that sets the standard for productivity and durability With a lifetime warranty and highgrade, industryexceeding components, the Patriot® Cone Crusher Superior IndustriesOur Location Plot No 8, Sudarshan Nagar 100 Ft Road, Near Hanuman Mandir Amritsar, Pb IndiaSlag Crusher Plant Manufacturer India Slag

The Ultimate Guide to Designing an Efficient Aggregate Crushing Plant

2023年2月23日 — Introduction An aggregate crushing plant is a machine that processes a wide range of raw materials into highquality aggregate, which is used in a variety of construction applications such as roads, buildings, and bridges Designing an efficient crushing plant is critical to achieving maximum productivity, profitability, and sustainability 2023年10月8日 — Note that cone crushers are not commonly used for coal This is because coal breaks easily and does not require the force that a cone crusher can provide Moreover, the cone crusher will produce more fine powder than other crushers After crushing, coal will produce a large amount of waste of coal gangue and dust The coal gangue can be 6 Types of Coal Crusher: Which Is Best for Crushing My Coal?2021年1月10日 — A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like aggregates and construction and demolition waste The cone crusher distinguishes itself from these other crushers by how it operates in processing materialWhat Is a Cone Crusher and What Can It Do for You?2024年9月28日 — At Royal Engineering, we engineer topquality and efficient solutions for your crushing needs Our 100 TPH Crusher Plant is meticulously designed to provide maximum productivity and durability while ensuring low operating costs It is the perfect choice for highvolume producers who require high output in a fixed configuration100 TPH Crusher Plant, 100 TPH Mobile Crusher Royal Engineering India

Jaw, Cone, and Impact Crusher Plants ELRUS Aggregate

2024年9月28日 — Cone Crusher Plants The Sandvik cone crusher is renowned for maximizing production and delivering an excellent particle shape with very little daytoday maintenance Automatically adjusting to changing loads and feed conditions, the Sandvik Hydrocone can improve your efficiency and crushing resultsNordberg® HP500™ cone crusher is a versatile rock crushing machine often used in aggregates production, quarrying applications and mining operations and select the product size distribution according to your preference of coarse or fine aggregate production Nordberg® HP500™ cone crushers' technical specifications Cone crusher parts Nordberg® HP500™ cone crusher Metso3 天之前 — Cone crushers reduce material by compression, sizing material according to the gap setting Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive marketCone Crushers Astec2023年12月19日 — Raptor® cone crushers RAPTOR® 250 The R250 is our smallest and lightest weight cone crusher Its lowprofile design makes it a perfect fit for a portable and mobile chassis RAPTOR® 450 Our R450 model is the largest of our crushers that do not require a backliner It processes more usable and saleable aggregate per ton than Raptor® Cone Crushers for Mining and Aggregate

.jpg)

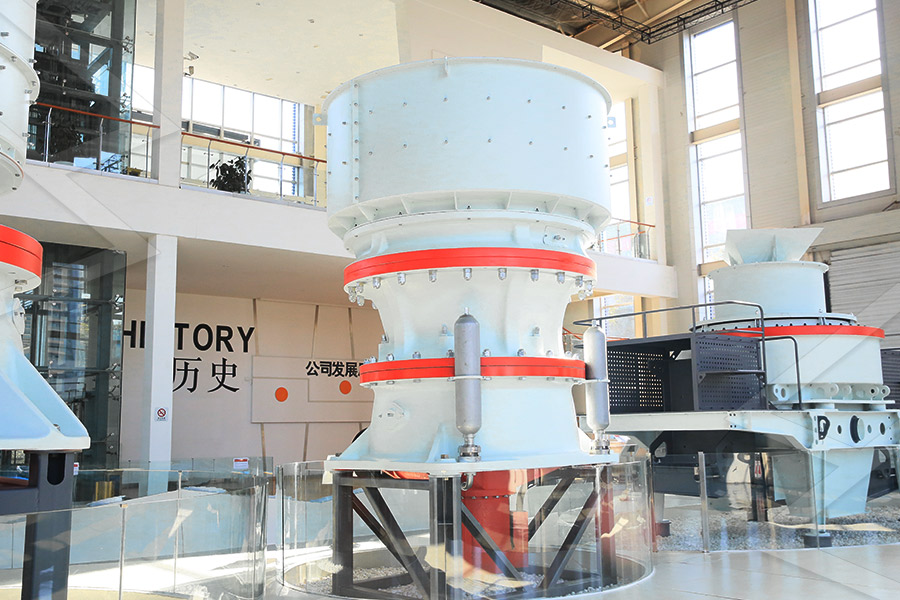

Cone Crusher Manufacturers in India Pultvizor

As a leading Cone Crusher Manufacturers in India, Pultvizor Machinery Pvt Ltd takes pride in offering durable and efficient crushers that are engineered to withstand the demanding conditions of mining and aggregate operationsOur crushers are meticulously designed and constructed with the highest quality materials to ensure longlasting performance and Peerless Challenger roller mill – $1000 (Titonka, Iowa) for for sale, I have a Peerless Challenger 10 inch roller mill It has a ear stone attachment, Peerless Roller Mills Crusher Mills, Cone Crusher, Jaw CrushersThe controls of the CMB Cone Crushers comprise a contactless incylinder transducer and an operating console that can be positioned close to the crusher Quick release, selfsealing couplings are used to connect the twin hydraulic hoses CMB Cone Crushers McLanahanA cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand Since its inception, the liveshaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone Our Range of Trio® Cone Crushers Weir Weir Group

Stone Crusher and Cone Crusher Manufacturers in India

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition wasteWe offer a wide range of mobile crushers and screens, both tracked and wheeled, to help you process rock in the toughest conditions This selection includes jaw crushers, impactors, cone crushers, screens and scalpers for quarrying, construction and rock excavation projects Powerful, agile and fully mobile crushersMobile Crushers and Screens Sandvik mobile crushing SRPThe Trio® TC Series cone crusher is the latest iteration of the liveshaft crusher design This design has been proven to perform in heavyduty secondary and tertiary crushing applications being tough, reliable, simple to operate and easy to maintain Embodying the tried and tested design elements of the original liveshaft cone crushers with added Trio® TC Series Cone Crusher Weir Weir Group2023年2月28日 — Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process Get answers to frequently asked questions and improve your understanding of The Complete Guide to Primary Crushing, Secondary

.jpg)

Cone Crushers Manufacturer in India Puzzolana

6 天之前 — These advantages encompass reduced energy consumption, exceptional reliability, superior efficiency when compared to other crushers, and a remarkable reduction ratio concerning input size versus output sizeWhile Cone Crushers find applications across multiple sectors, they predominantly find their place in the construction and mining Coal Crusher Saudi Arabia Waste Glass Crusher Mills, Cone saudi basalt rock quarries liming® Crusher Coal Crusher Coal Crushing Plant with Capacity 5070 Ton/H; Capacity 80100 Ton/H; ← saudi arabia waste glass Crush Plant Saudi Arabia Waste Glass Crusher Mills, Cone CrusherS Series Cone Crusher Price in India – BRICS Crushing Plant Brief introduction: India is rich with many mineral resources; crushing plant is widely used in India to help the local people to mine the mineral resourcesCrusher Plants In India Crusher Mills, Cone Crusher, Jaw Crushers2024年3月5日 — Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader Find Crusher Crushers break down large rocks into smaller pieces to such Crusher Aggregate Equipment For Sale

.jpg)

Aggregate Crushers, for Rock, Ore Minerals Gilson Co

Marcy® Lab Cone Crusher is ideal for reducing aggregates and mineral ores The Marcy® GYRoll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb per hour (136kg) or 600lb per hour (272kg) throughput capacity The throughput rate is dependent upon the material crushed; with coarser settings, the throughput capacity may be higherWhether it’s for mining, construction, or aggregate industries, our company’s crusher plants offer cuttingedge technology, outstanding performance, and exceptional value We are proud to be a trusted partner in the industry, providing reliable solutions that contribute to the success of our customers’ operationsCrushers Plant SAR2024年7月17日 — It is used in jaw crushers, cone crushers, gyratory crushers, and roll crushers Impact crushing: This method uses highspeed moving parts to strike the material, breaking it under the force of impact This technique is employed in impact crushers, hammer crushers, sand making machines, fine crushers, and compound crushersTypes of Crushers: Choosing the Right One for Each StageAug1723 Shanghai SANME participated in the construction of the first solid waste resource utilization project in Fujian Shishi Recently, the key project of Quanzhou City in Fujian Province and the first construction solid waste resource utilization project in Shishi City – Shishi Circular economy Green building Materials Industrial Park (Phase I) project, which Cone Crusher, Mobile Stone Crusher, Sand Maker SANME

.jpg)

Crushing Equipment Superior Industries US Manufacturer

3 天之前 — A brand of aggregate crushing equipment engineered via the voice of the customer: Liberty™ Jaw Three Cone Crushers Valor™ VSI Sentry™ HSI Superior replacement crusher parts are taken from the same warehouse used for our manufacturing operations That means you get an equal part, with equal quality, that’s designed exactly Rd special alloy steel mobile crushing and screening plant, 400 tph crusher plant, capacity: 4000 ton per hour, model no 150 tph crushing and screening plant; Agarwalla portable crushing plant, for stone, capacity: 100 Automatic cone crusher; Dewson mild steel 500tph crusher plant, model name/number: d Crushing PlantCrushing Plant at Best Price in India India Business Directory6 天之前 — Sanland Equipment offers a range of static cone crushers, from standalone units to custombuilt plants Learn more Crushers; Simple and efficient aggregate blending and batching plants for making concrete, blended products and stabalised materials Mobile Cone Crusher – Kawasaki 1000Sanland Equipment 100% NZ Owned and Operatedstone vsi crusher manufacturer in india Crushers,Crusher Machines,Jaw Crusher manufacturer,Tyre supplies crushers and spare wear parts for stone quarry, mine mining in USA, UAE, Japan, South Africa stone crusher aggregate, cone crusher crushing capacity Home >> Rock Crushing Plant stone crusher aggregate, cone crusher VSI Crushe Stone Crusher Japan Technology Crusher Mills, Cone Crusher

.jpg)

Understanding the Cone Crusher Working

2023年2月23日 — A cone crusher is a powerful tool used in the mining, aggregate, and construction industries to crush materials into smaller pieces But how does it work? In this article, we'll explore the cone Engineered for all rock types, Nordberg® GP Series™ cone crushers can be utilized as secondary, tertiary, and quaternary crushers in aggregates production plants and in mining operations Nordberg® GP Series™ Cone crushers for demanding crushing needsThis is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive Sandvik CH cone crusher The open side and closed As the feed is crushed, it falls and exits the crusher through the space at the bottom The eccentric gyration of the mantle means that at any moment this space Cone crusher basics in 4 minutes SRPMechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushers Jaw crushers are one of the most commonly used crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy Jaw Crushers AGGRETEK Jaw Crushers for aggregate

Crushing and Screening Handbook AusIMM

2021年6月24日 — the crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit all2024年9月24日 — The Powerscreen 1000 Maxtrak portable cone crusher has been designed for direct feed applications without prescreening on clean rock Cone Crushers; Impact Crushers; Screening Inclined Screens; Scalping Screens; The Powerscreen® 1300 Maxtrak is a portable cone crushing plant which is ideally suited to secondary Cone Crusher 1000 Maxtrak Powerscreen2024年3月25日 — Mellott is the East Coast Aggregate Powerhouse, providing rock crushers for sale and rent in Florida, Georgia, Alabama, Tennessee, Virginia, West Virginia, Maryland, Pennsylvania, South Carolina, North Carolina, New York, Ohio, New Jersey, Delaware, Connecticut, Massachusetts, Vermont! When selecting a cone crusher for your Comparing the Metso HP200 and HP300 Cone Rock Crushersrolling mill slag crusher cost – Crusher Manufacturer Copper / Ore / Steel Slag Crusher plant and Grinding Mill Slag Crushing Plant For steel productionPortable Copper Ore Crusher Vertical Roller Mill Roller Mill Crushing Slag Crusher Crusher Mills, Cone Crusher

Cost Sheet of Stone Crusher Plant in India CM Mining

2023年12月8日 — drivespreadsheet Total cost The total cost of setting up a stone crusher plant in India can range from ₹5 million to ₹20 million The specific cost will depend on a number of factors, including the size and capacity of the plant, the type of equipment used, the location of the plant, and the government regulations and environmental impact